New Recycling and Energy Conversion for Electronic Waste Project

Pioneering a Next-Generation Recycling Model to Solve Labor Shortages and Environmental Challenges

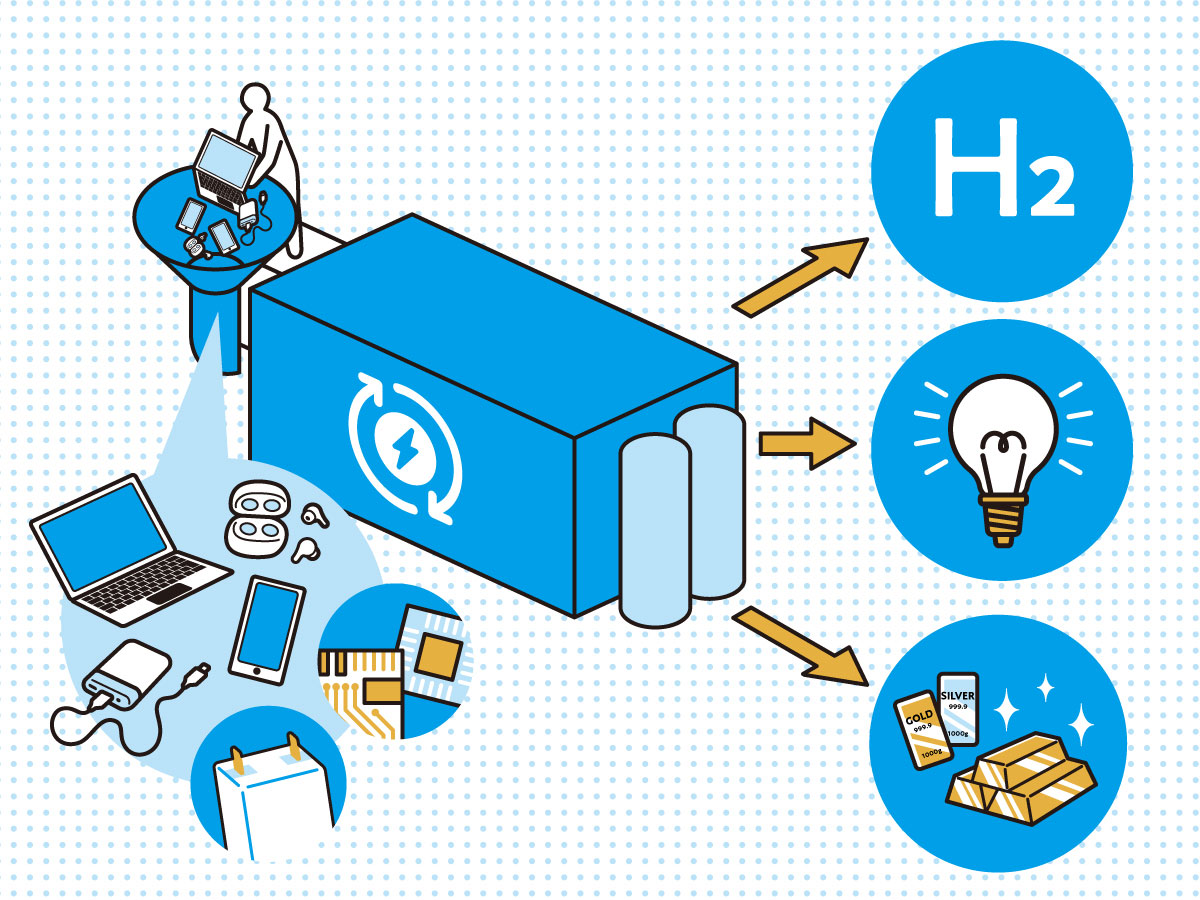

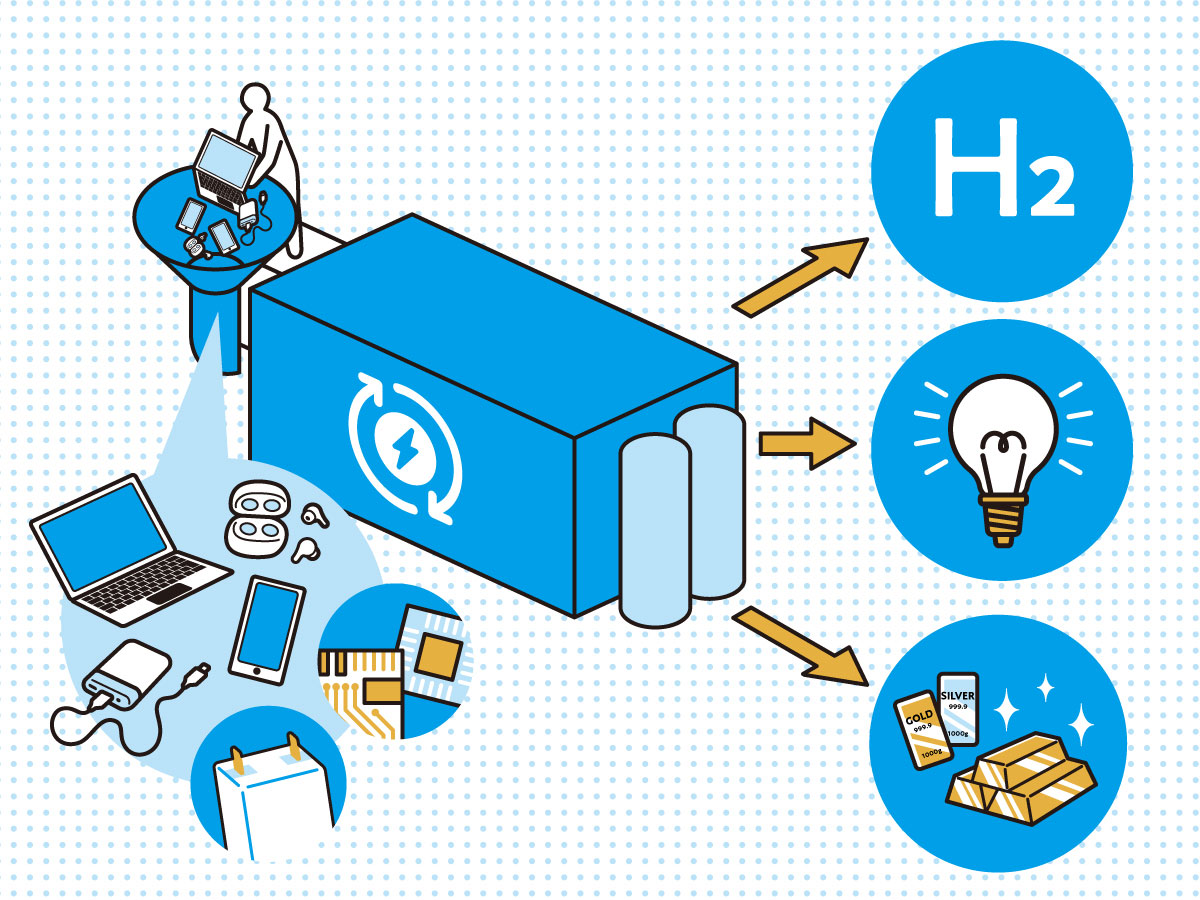

Used smartphones, laptops, and other compact electronics contain valuable metals like gold, silver, and rare metals. These rich deposits are often referred to as "urban mines", and Japan is believed to hold some of the largest reserves in the world.

As a resource-limited country, Japan can benefit significantly from recovering these materials. Doing so can reduce dependence on imports, lower environmental impact, and unlock new economic value.

However, conventional recycling methods still rely heavily on manual labor. Devices often contain lithium-ion batteries that pose explosion risks if handled improperly, requiring time-consuming and delicate work. With the growing trend toward smaller and more compact designs, such as earbuds and micro-gadgets, identifying and separating components has become increasingly challenging.

At the same time, Japan's aging and declining population is making it more difficult to secure the labor needed for recycling operations.

To address these challenges, we are launching a pilot project this autumn in partnership with a recycling company. The project will introduce, a Waste-to-Energy system (EnviroFusion) that transforms electronic waste into electricity.

WTE system uses resin from circuit boards as a fuel source, while melting and recovering valuable metals. It will also test the safe neutralization of lithium-ion batteries in oxygen-free, high-temperature environments.

Our goal is to reduce the labor demands and risks of e-waste recycling while generating energy. Looking ahead, we aim to develop a model that improves the recovery rate of urban mines and converts resin waste into feedstock for hydrogen energy.

Further details will be announced soon.

Used smartphones, laptops, and other compact electronics contain valuable metals like gold, silver, and rare metals. These rich deposits are often referred to as "urban mines", and Japan is believed to hold some of the largest reserves in the world.

Used smartphones, laptops, and other compact electronics contain valuable metals like gold, silver, and rare metals. These rich deposits are often referred to as "urban mines", and Japan is believed to hold some of the largest reserves in the world.